Description

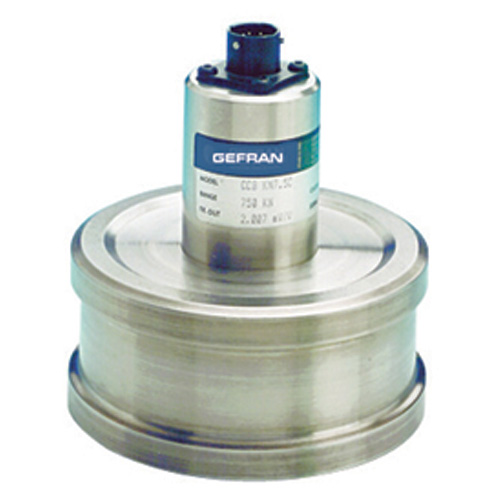

The CC force transducers have been designed for use in the plastics industry where it is required to measure the reaction force to the extrusion pressure that is present on the casing of the gearbox along the axis of the extruder screw.

These models, fitted in contact with the thrust bearings, measure a force whose valve, after suitable correction, is equal to extrusion pressure multiplied by the screw area. The CC cylindrical force transducers are all stainless steel construction and configured in such a way that the body, airtight welded, acts also as the case, making a unit that is smaller than the CT series.

The connector in the shank is on the same axis as the transducer, which in some cases alows easier installation.

TECHNICAL DATA OF CC

| Accuracy | 1% |

| Nominal full scale load (Ln) | 750…1500 kN |

| Nominal output at FSO | 2mV/V |

| Output tolerance at Ln | <± 1% FSO |

| Combined errors: Non linearity Histeresis, Repeatibility | < ± 1% FSO |

| Creep (after 30 min. at Ln) | < ± 0,06% FSO |

| Zero load out of balance signal | < ± 1% FSO |

| Calibration signal * | 80%FSO ± 1% |

| Thermal drift in Sensitivity compensated Zero range Calibration | < ± 0,02% FSO°C < ± 0,02% FSO°C < ± 0,02% FSO°C |

| Nominal input resistance | 700 Ohm |

| Isolation resistance | > 10 GOhm |

| Nominal supply voltage | 10 V |

| Maximum supply voltage | 15 V |

| Compensated temperature range | -20…+50°C |

| Maximum temperature range | -20…+60°C |

| Storage temperature range | -30…+80°C |

| Permitted static load | 130% Ln |

| Maximum applicable load | 150% Ln |

| Rupture load | > 300% Ln |

| Carico statico laterale max. | 40% Ln |

| Maximum elastic deformation at Ln | < 0,1 mm |

| Grade of protection (DIN40050) | IP65 |

| Electr. connections: Connector | VPT02A10-6PT2 |

| Elastic element material | Stainless steel |

| Case material | Stainless steel |

| * The exact value is indicated on the instrument nameplate. | |

Reviews

There are no reviews yet.